Dongte (China) Metal Products Sales Co., LTD

PRODUCT CENTER

CONTACT US

If you are interested in cooperation, please contact us immediately, we will give you feedback as soon as possible!

Mobile

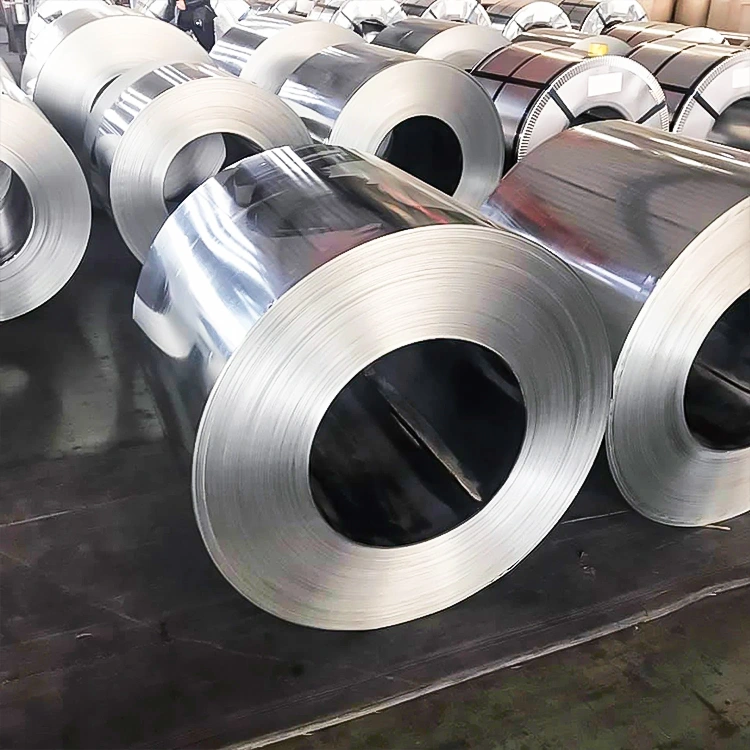

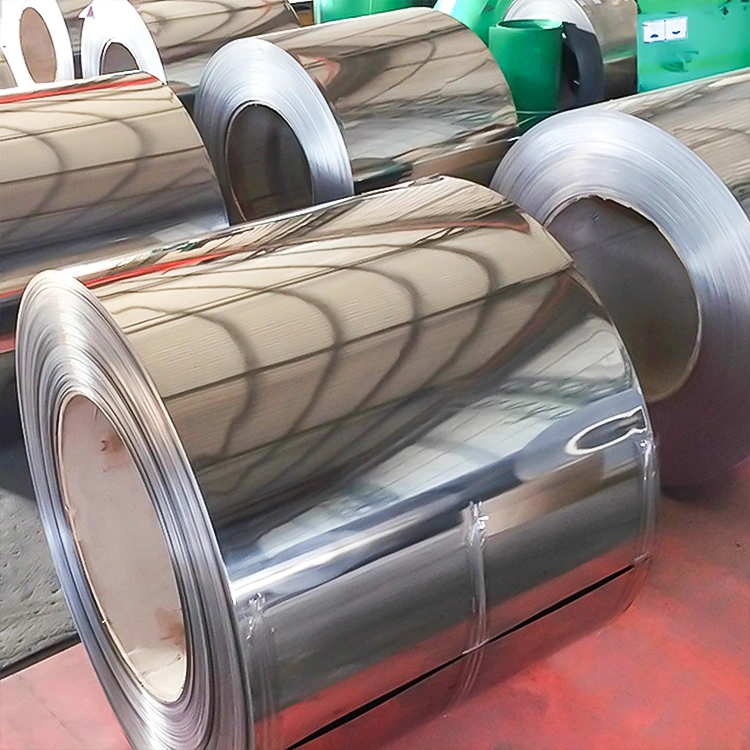

Stainless Steel Coil

304 stainless steel coil is a low carbon, molybdenum bearing, austenitic stainless steel coil. Its chemistry features a minimum of 18% chromium and 8% nickel.These grade stainless steel coils are used for its corrosion resistance to many chemical corrodents, in addition to having good mechanical properties.

VIEW MORE +

316L stainless steel coils have many applications including chemical processing, food handling equipment and marine applications. They can be used in the fabrication of containers for high temperature corrosive liquids and gases such as petrochemicals, chemical feedstocks and liquified natural gas.

VIEW MORE +

430 stainless steel coil is a high quality alloy that is known for its corrosion resistance and high strength properties.They have better thermal conductivity than austenite grades stainless steel coils, a smaller thermal expansion coefficient than austenite strip, heat fatigue resistance.

VIEW MORE +

310S stainless steel coil is austenitic chromium-nickel stainless steel with good oxidation resistance and resistance, corrosion and high temperature resistance.Because of the higher percentage of chromium and nickel, it has much better strength, can work continuously at high temperature, and has good high temperature resistance.

VIEW MORE +

The alloy composition of 2205 contains molybdenum, chromium and nitrogen. The addition of molybdenum provides resistance to pitting and crevice corrosion in chloride environments. Chromium improves the corrosion resistance in sulfate environments, whereas nitrogen enhances its resistance to stress corrosion cracking.

VIEW MORE +

321 stainless steel coil is a free-machining austenitic chromium-nickel austenitic alloy (18% Cr, 12% Ni) that provides good corrosion resistance in a wide range of corrosive environments.321 stainless steel coils are widely used in the chemical and petrochemical industries where its corrosion resistance properties can be put to good use.

VIEW MORE +

CONTACT US

Email:sales04@zgdtsteel.com

Phone : +86 18053180867

WeChat : +86 18053180867

WhatsApp : +86 18053180867

GET A FREE QUOTE

Copyright : Dongte (China) Metal Products Sales Co., LTD 鲁ICP备2022034553号-1 Seo Tags